Automatic Self-Cleaning Strainers / Automatic Backwash Strainers

Automatic self-cleaning strainers are fluid filters that utilize system pressure to keep themselves clean. By removing large particles and debris from flowing fluid, these self-cleaning strainers are capable of saving money on energy, water, equipment replacement, and maintenance.

These filters are called automatic self-cleaning strainers because, unlike several other systems, this advanced technology does not require any routine maintenance. There is no need for constant change-outs or system shutdowns such as a bag or cartridge filter.

The Eliminator®

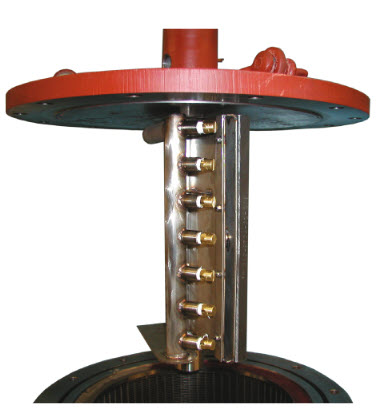

The Eliminator® Series strainers are automatic and motorized self-cleaning strainers designed by Fluid Engineering. They can provide continuous debris removal from the fluid piping systems that demand an uninterrupted flow.

Downstream flow is not interrupted during the backwash cycle!

These strainers are also quite effective in fluid applications that have high solids, unattended service, and uninterrupted flow requirements. They consider a basket strainer and their attendant maintenance problems quite impractical.

When the Fluid Engineering 723 – 793 – 753 Strainers are correctly applied, they turn out to be one of the most cost-effective efficient strainers compared to the standard or duplex options.

Hyper-Jet®

Another good example of an automatic self-cleaning strainer is 721 – 751 Hyper-Jet, a proven and patented filtration solution. This one is more effective in fluid applications where there is the need for uninterrupted flow and unattended service.

Downstream flow is not interrupted during the backwash cycle!

The solid particles and debris get caught in the strainer screen, and when they are removed, the strainer backwashes. During the backwash cycle process, the downstream flow does not get interrupted. The Hyper-Jet further adds internal spray nozzles that are powered by a high-pressure external source to aid in cleaning.

There are various strainer housings and screens also available in numerous materials and configurations to help meet the many applications, including the geminate, Didymosphenia, more commonly referred to as a didymo rock snot.

Please contact us with the specifics of your project / Request an Estimate:

we’d like to be of assistance!

Here are some of the benefits of using Automatic Self-Cleaning Strainers:

- Improved Efficiency: Can remove debris and contaminants from liquids more efficiently than traditional strainers. The self-cleaning mechanism ensures that the strainer remains clean and free of debris, which reduces the risk of clogging and increases the flow rate of the liquid.

- Reduced Downtime: Can operate continuously without the need for human intervention, which reduces downtime and maintenance costs. This is particularly important in industries where downtime can result in significant financial losses.

- Increased Productivity: By reducing downtime and increasing efficiency, automatic self-cleaning strainers can increase productivity. This allows industries to produce more products in a shorter amount of time, which can lead to increased revenue and profitability.

- Improved Quality: Can improve the quality of the final product by removing contaminants and debris from liquids. This is particularly important in industries such as food and beverage, pharmaceuticals, and water treatment, where the quality of the final product is critical.

- Cost Savings: While the initial cost of automatic self-cleaning strainers may be higher than traditional strainers, they can result in significant cost savings in the long run. By reducing downtime, maintenance costs, and improving efficiency, automatic self-cleaning strainers can save industries money over time.

Overall, automatic self-cleaning strainers offer a range of benefits for industries that rely on the efficient and continuous operation of liquid filtration systems.